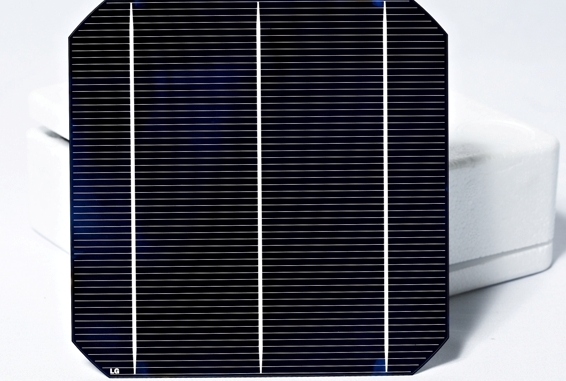

LG research develops solid module improvement

The Solar business unit of LG Electronics announced today a new innovative technology to which the light-induced degradation (LID) in p-type monocrystalline solar cells based may be reduced by up to 80%.

LG Electronics' new technology can easily be integrated in existing production lines. The new technology does not require other raw materials for the production or a change in the p-type-based monocrystalline silicon structure.

The phenomenon of light-induced degradation (LID) affects the performance of solar cells and modules, shortly after they are exposed to direct light. This effect in the past has been seen as inevitable in the PV industry, particularly at p-type based solar products.

The output loss due to LID can range from 2 to five percent of the actual specification of the respective module in the 1st year. The boron-oxygen compound in the cells is the main cause for the light-induced degradation.

The suggestion of many researchers has been to replace gallium-doped silicon wafers instead of Boron-doped ones with the lower oxygen concentration resulting in reduced LID. Nevertheless the relative high cost of this process and complex production processes has made implication not practicable. The new LG technology process allows the boron-oxygen connection to be suppressed, therefore allowing only limited LID-effects to take place.

"LG Electronics is investing large amounts in the research area and this new manufacturing process is another result of our tireless research efforts. Thanks to the latest findings, we are able to provide our customers with reliable and cutting edge solar technology at competitive prices“, said Markus Lambert, National Sales Manager, LG Solar.